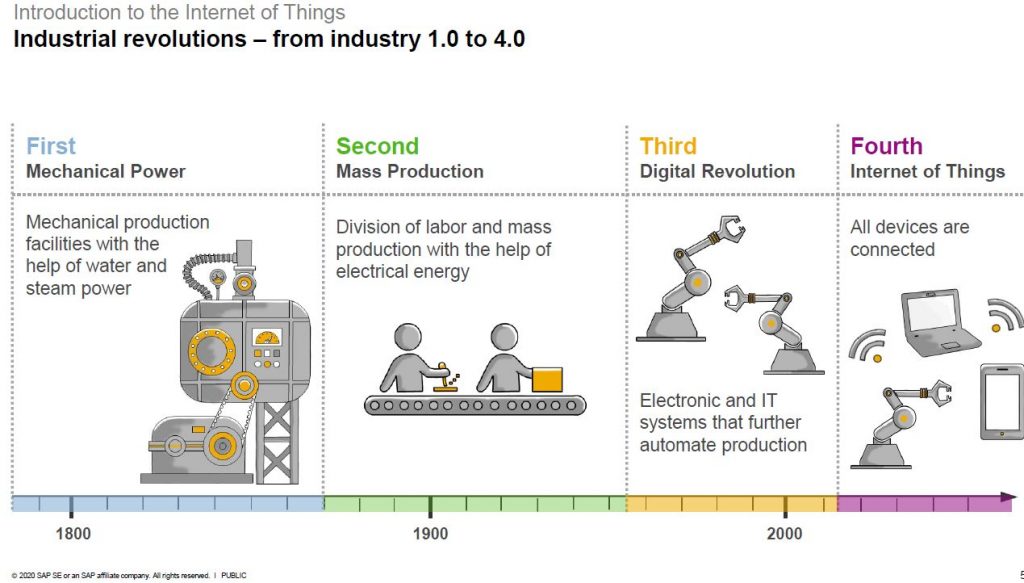

Industry 4.0 is mostly managed by the connected devices. The data is collected at / very near to the source in real time, Colloborated with supporting data. It is later processed and presented for the decision makers. Along with this Artificial Intelligence, Machine learning etc help business also to prevent / predict the outcomes.

The innovation in the sensors, Processing the data with edge processors, Storing and processing the data on premise or on cloud is helping many of the enterprises to adapt the Industry 4.0.

When there are many advantages detailed , the common challenges on Business benefit (RoI), Data privacy, Legal regulation are also travelling together. Some of them take bold steps to adapt on the go.

With the communication technology already marching towards 5G+ technologies , this Industry 4.0 will be a mandatory knowledge area which needs to be upgraded / adapted to stay in the game. Let us continue to learn and Share.

Series: Industry 4.0