![]()

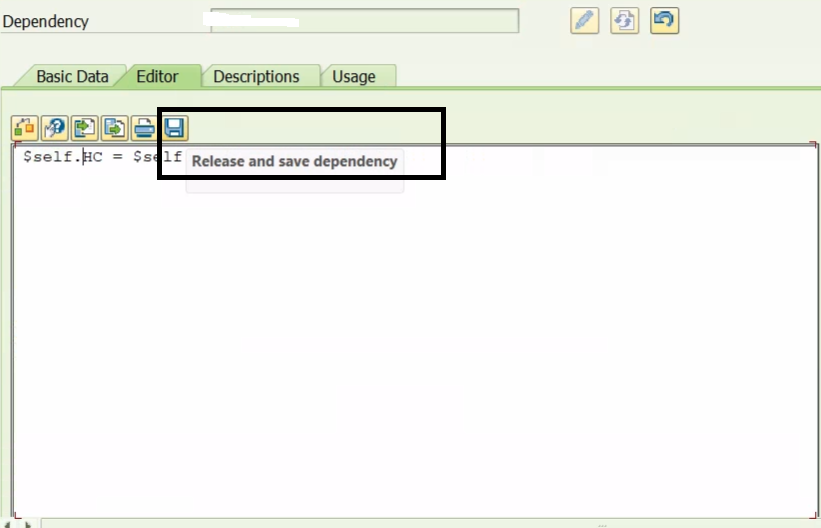

SAP has introduced a small but powerful improvement in PMEVC — a new toolbar button that lets you release and save a dependency in a single click. This gives a Cleaner navigation experience in PMEVC and Reduced clicks + Time saving No more jumping to the Basic Data tab. No more extra navigation. Just clean, fast modeling!

🔍 What’s New? (Simplified)

🆕 New toolbar button

- Release + Save dependency at once

Works for both:

- 🔸 Local dependencies

- 🔸 Global dependencies

⏱️ No more tab switching

- Skip the Basic Data tab completely

- Smoother, faster modeling

workflow

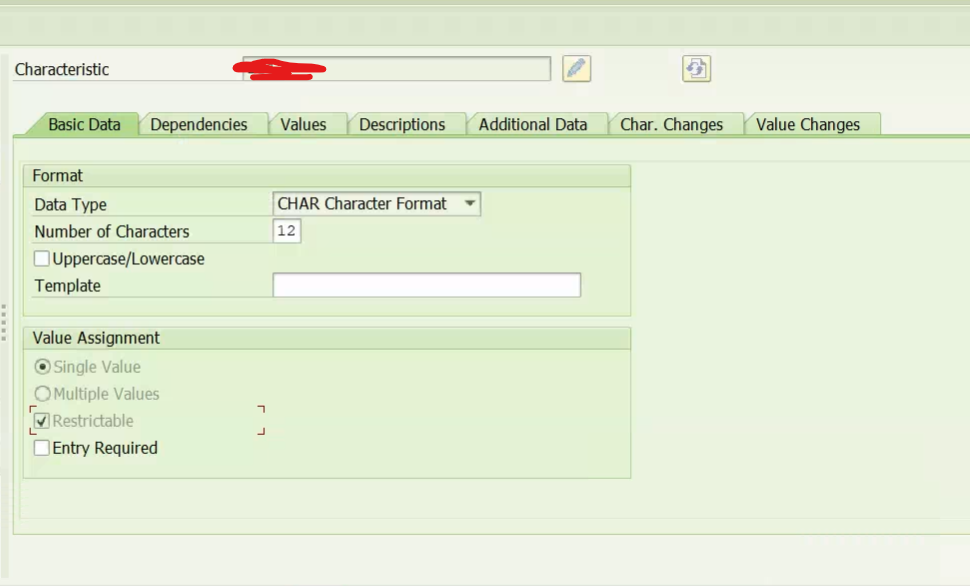

💡 Perfect for AVC consultants working with frequent dependency updates.

If you work with dependencies daily, activate this note and upgrade your modeling speed instantly.

Need help refining dependencies or optimizing AVC design? Feel free to reach out!

Note: 3486340 – PMEVC: Release and save dependency at once

#SAPAVC #VariantConfiguration #SAPS4HANA #PMEVC #SAPDependency #SAPConsulting #AVCExpert #SAPManufacturing #SAPTips #SAPNote