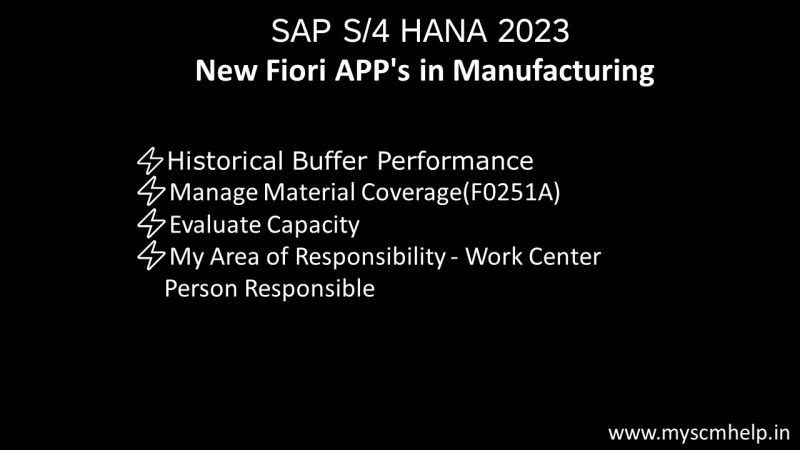

🎯 SAP S/4 Hana 2023: New Fiori APP’s in Manufacturing

![]()

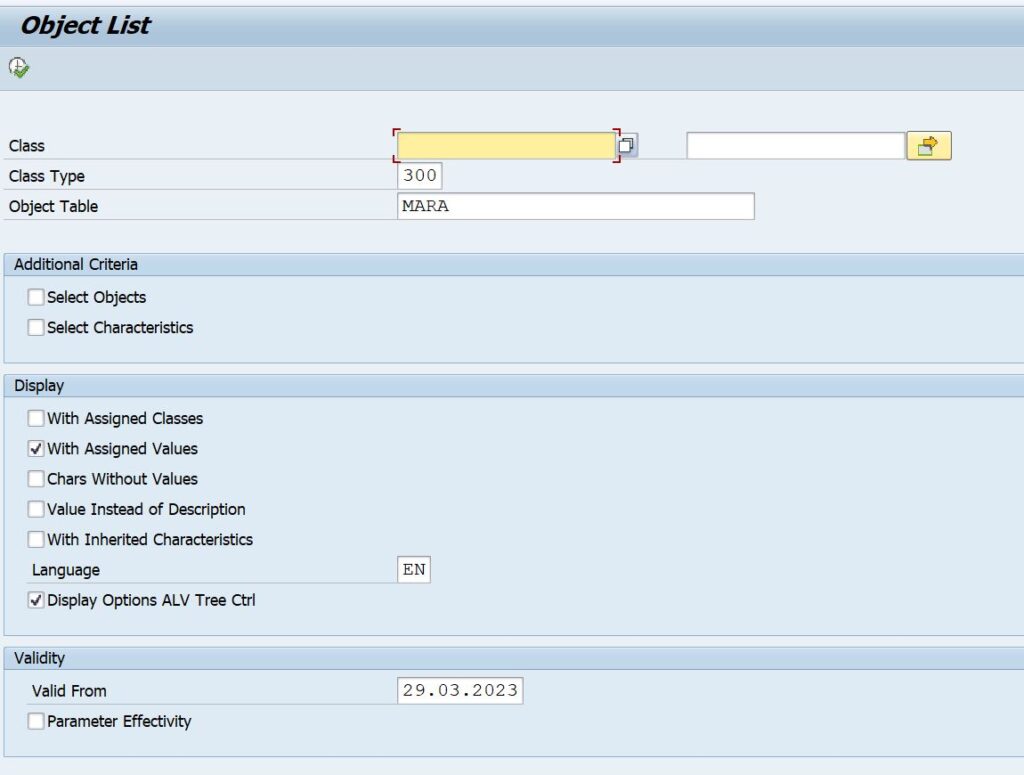

The below are the list of New apps that have been released in SAP S/4 Hana 2023 in the Manufacturing LOB

⚡ Historical Buffer Performance –

is a new app using which you can view the historical data for your buffer stock related to the time-dependent buffer level charts within a specified time period (for example, last month). The visualization and analytical capabilities helps the production planner to gain an insight into the historical buffer performance for a material.

⚡Manage Material Coverage(F0251A) –

With this app, you can display and analyze coverage issues that exist for selected materials. For each material that you select, you can display a stock / requirements list including material shortage information, which helps you determine shortages that can cause disruptions to production or to the fulfillment of customer demands. You can also take actions directly from the app, for example, start an MRP run or edit MRP elements to resolve coverage issues

⚡Evaluate Capacity is a new app using which you can better visualize capacity situation of work centers within a plant. You can group work centers based on work center group and visualize the utilization on the group level. The visualization and analytical capabilities helps in understanding and managing the impact of capacity situation.

⚡My Area of Responsibility – Work Center Person Responsible

With this new app, you can define your area of responsibility by selecting the respective combinations of plant and work center person responsible. In the Mass maintenance of work center capacities app, only those work center capacities are displayed in the worklist that fulfill your selection criteria.

Advance Variant Configuration(AVC) & VCH_HL_AFL_CHECK

![]()

⚡Advance Variant Configuration(AVC) &VCH_HL_AFL_CHECK⚡

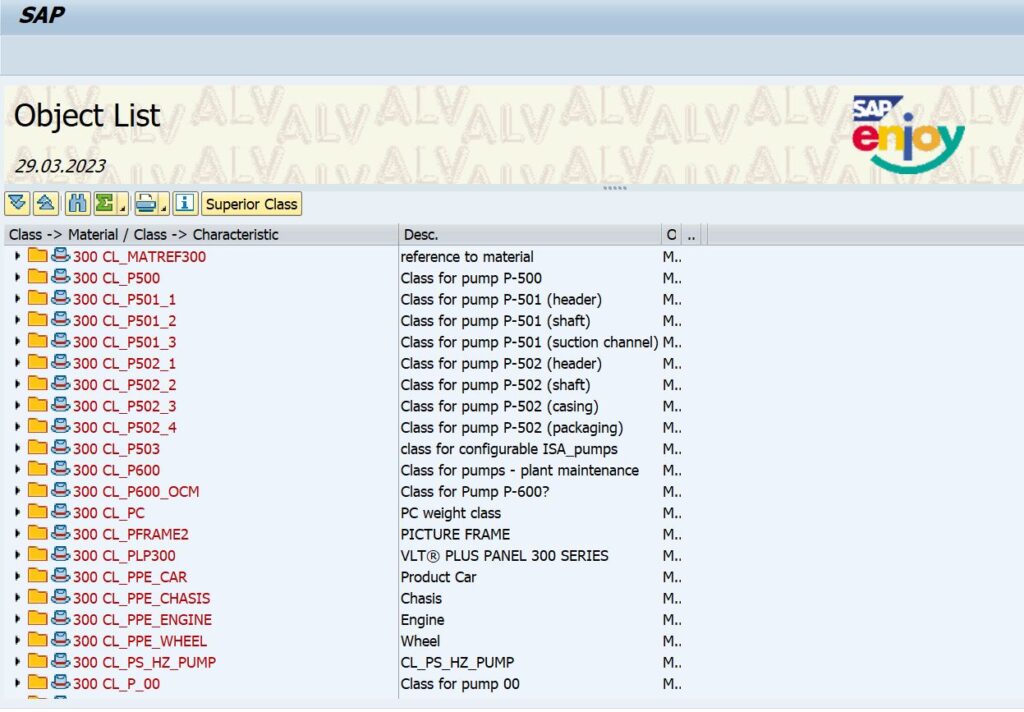

🎯 As we know the AVC has to be installed after the S4 Hana has been installed. This can be part of your upgrade or even for new installation

🎯 It is always important to evaluate if all the Technical Pre-Requisites are completed correctly

🎯 This is completely as Technical task for validation but still it is good for the Functional consultants also to be aware of this Pre-Requisites.

🎯 SAP has provided a standard report -VCH_HL_AFL_CHECK which will help you to execute and confirm the same.

🎯 There are parameters which are more technical but the important part is you should be getting a message -“Procedure Called Successfully” in Green Highlighted color. This confirms that the technical pre-requisites are installed correctly.

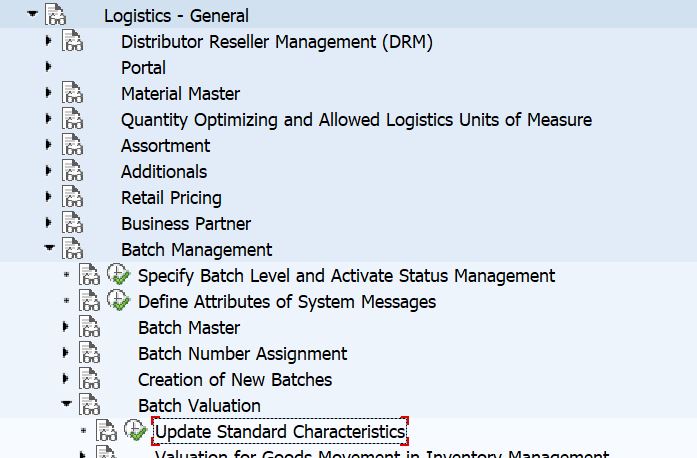

Batch Management – Standard Characteristics Creation.

![]()

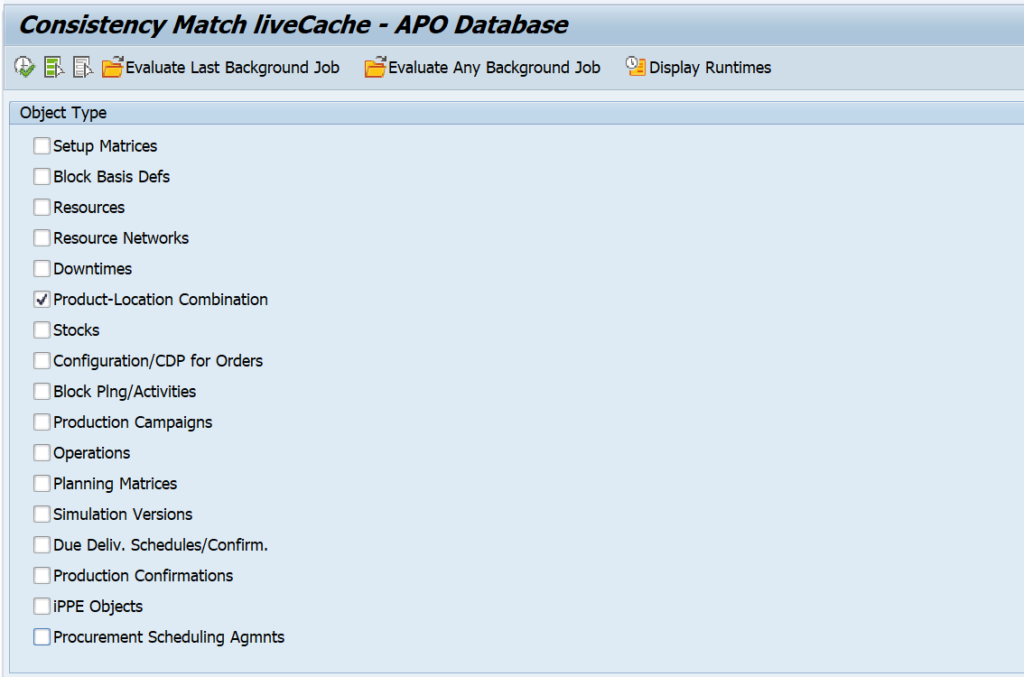

This blog details the process to update/ create the standard batch characteristics in the SAP – system.Whenever a new client is built you will not be finding the SAP – Standard characteritics. This concerns all characteristics starting with LOBM_*.

Example:

- LOBM_VFDAT expiration date, shelf life

- LOBM_VERAB availability date

To activate this we need to perform the below customization in the system.

This particular acvitity is to be peformed during the below cases:

- In newly created clients, after copying other clients

- After defining object dependencies for standard characteristic LOBM_RLZ

- In every client after a release upgrade

The configuration Path is as below :Logistics – General> Batch Managment > Batch valuation > Update Standard Characteristics. Once you run this configuration node , the standard cstics will be created and also the requried Object dependencies will also be creatd ( Copied from the client 000). This should be part of all new client preparation check list, cutover check list also.

Conversion factor of single-unit batch.Message no. MILL101

![]()

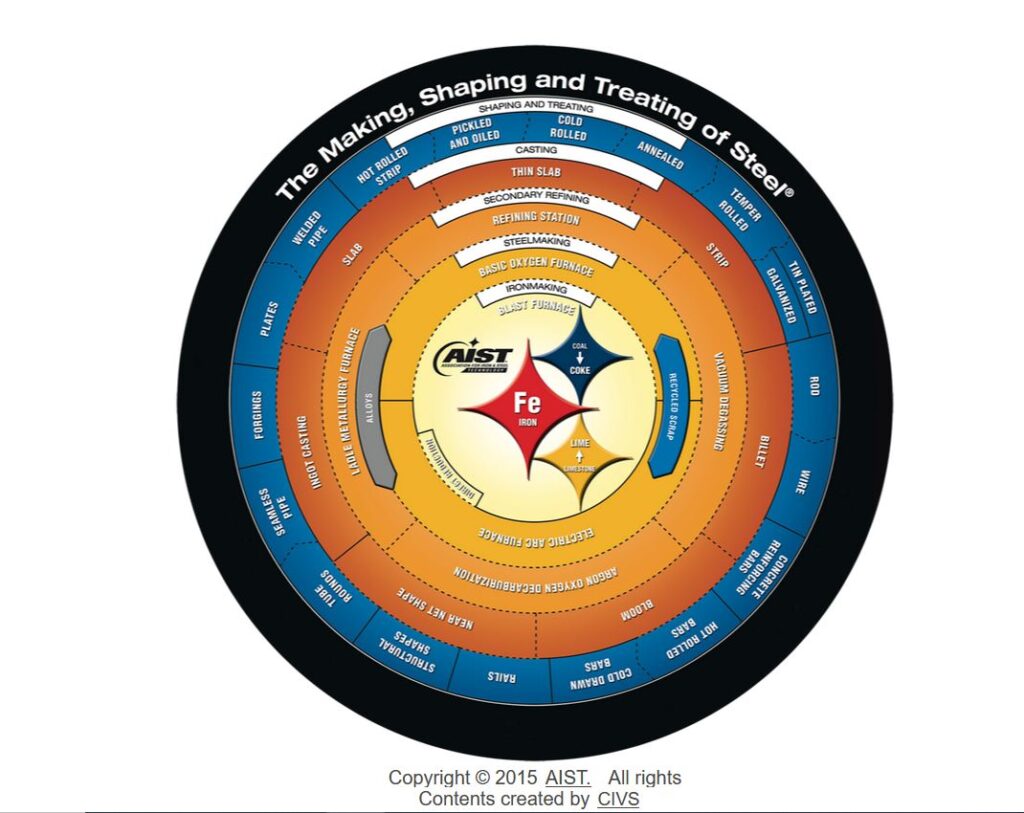

In case if you are facing the below error , espcially in case if you are using the IS-Mill functionality or the single unit batch concept.

Conversion

factor of single-unit batch Message no. MILL101.

This message is received if there is any inconsistency in the Batch specific unit of measure that has been adopted in the batch classification, Especially when you make return delivery or other cancellations if the Batch specific uom characteristics is not empty then this error will occur.