Earlier, People used to discuss on the version of SAP like 4.7 or ECC then ECC5 /ECC6 etc.

But currently the trend is about what EHP levels we are exposed and how much new functions we are aware of.

What is EHP ?

SAP delivers all the new functions that are delivered for different modules in a one single package called EHP.

So when you upgrade to the EHP 5 to EHP6 technically all the new EHP6 functionalities will be made available in the system

But there are instances that few functions needs to be activated in the Business Framework to make it work. This is because not all the new functionalities in the EHP6 will be applicable to the business.

To know about the new functions in each of the EHP kindly CLICK HERE.

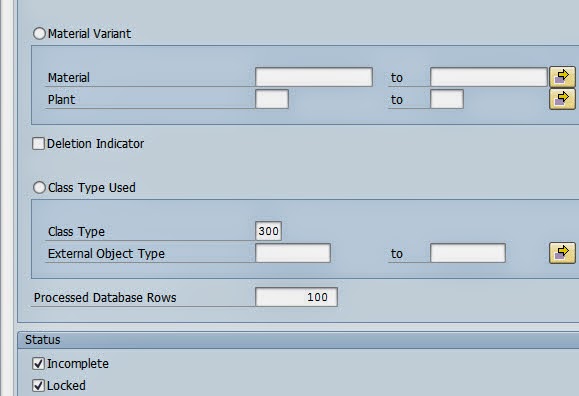

This link will take you to the screen like below and from there is it self explanatory.

Do leave a comment of what lates EHP levels you are working and what functionality is being used by you.